Vibration measurement equipment Types AV332x Series

All in one for vibration measurement equipment

Types AV332-UW series consists of triaxial MEMS Accelerometer, CPU, flash memory, USB and WIFI. The built-in CPU can be used as a high performance frequency analyzer using FFT or digital filters. The built-in flash memory enables machine health monitoring using frequency analyzed data. Therefore, it is a very powerful system that can frequency analyze vibration signals in a very small body to constantly monitoring whether the vibration signals are within the specified range and indicate an immediate abnormality when out of range. Types AV332-UW series can be simply used as a three-axis accelerometer, but its powerful built-in features make it simple to build systems for vibration measurement and diagnostic purposes, and will bring enormous cost savings.

Issues & Solution related to AV332

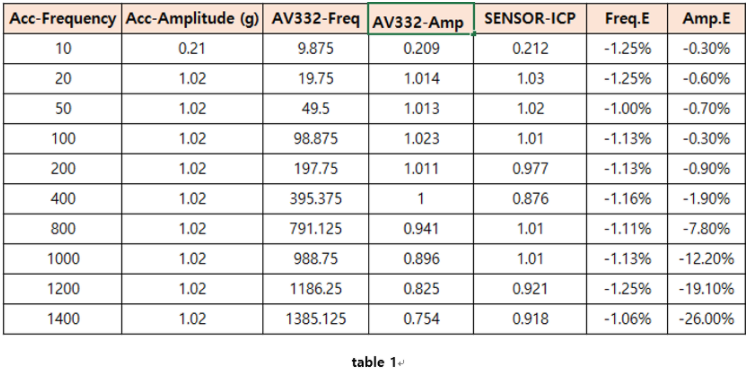

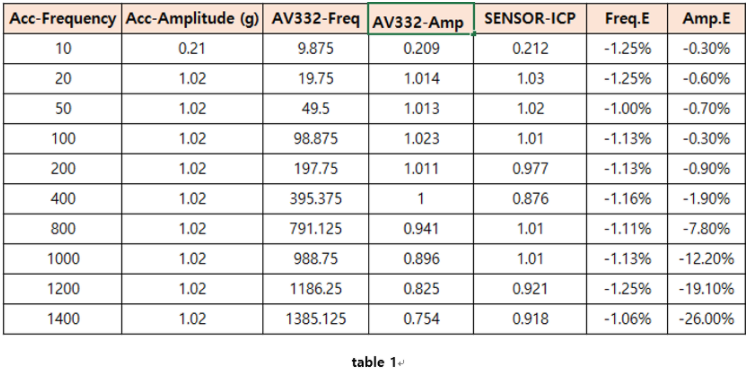

Recently, complaints about sensor performance have been received from customer who are considering a volume purchase for our MEMS Accelerometer AV332 model. The customer sent the performance comparison table via email between the AV332 and their ICP Accelerometer by using the B&K calibration system as shown in the table below.

AV332 has a 3200Hz frequency span, but customers wanted to perform machine conditioning

monitoring up to 1000Hz, so

AV338's Output Data Rate (ODR,sampling rate) was set to 3200 and tested.

There are three issues raised by customers as follows.

- Delta frequency is not an interger.

- Attenuation starts before 1000Hz.

- Frequency error occurs more than 1%.

Issue 1. Delta frequency is not an integer.

The frequency span of 3200 ODR(sampling frequency) is 1600 Hz.FFT analysis requires 2n data, so if you analyze it with 2048 samples, you will get 1,024 frequency analysis data.

Delta Frequency is 1600/1024=1.5625

Since the frequency interval is an integer multiple of 1.5625, it is inconvenient to read frequencies.

Solution 1-1. DFT analysis

DFT analysis with 1,600 data results in 800 frequency analysis data. Therefore, Delta Frequency is 1600/800=2.However, DFT may not be a good solution. DFT has a slower operation than FFT.

Solution 1-2. Synthesis 1024 line to 800 line

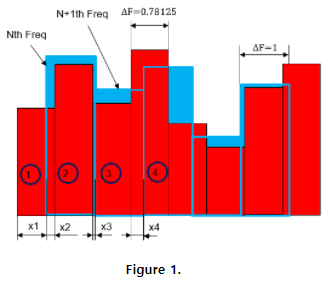

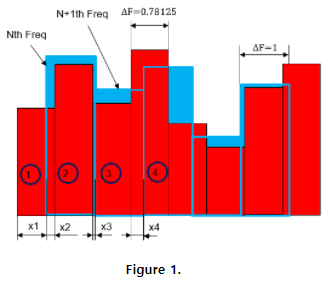

Consider Delta Freq. as 1. Then Delta Freq. of 1024 line is 0.78125, and Delta Freq. of 800 line to be synthesized is 1.

The spectrum obtained by line 1024 was marked in red. And the graph to be synthesized with 800 lines is shown in sky blue.

Nth Freq. is a part of the red graph ①, ② the whole, and a part of ③.

Nth Freq.= amp①*x2/(0.78125)+ amp②+amp③*x3/(0.78125)

(N+1)th Freq. is a part of the red graph ③ and part ④.

It can be calculated as (N+1)th Freq.= amp ③ * (0.78125-x3)/(0.78125)+ amp ④ * (0.78125-x4)/(0.78125).

Issue 2. Attenuation starts before 1000Hz.

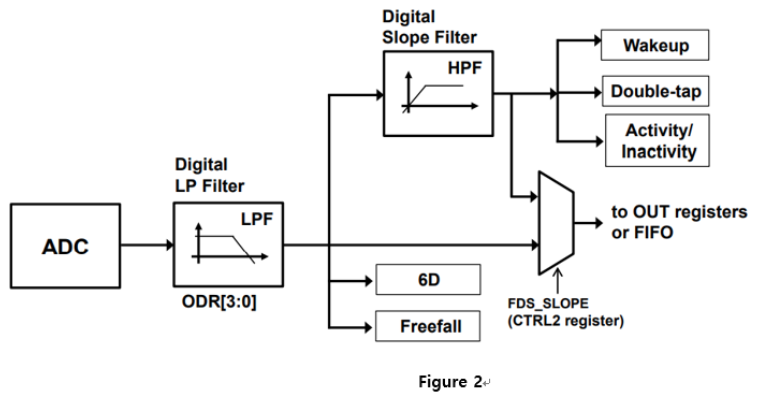

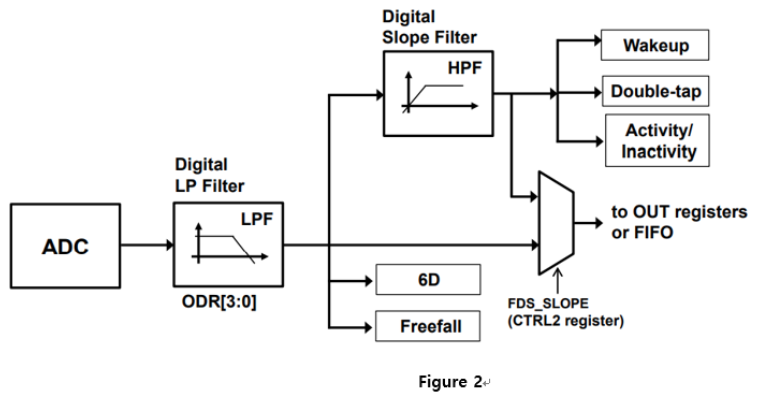

The structure of the general MEMS Sensor is as follows.

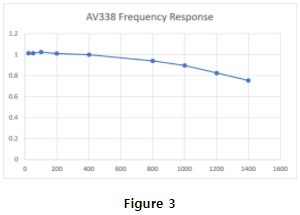

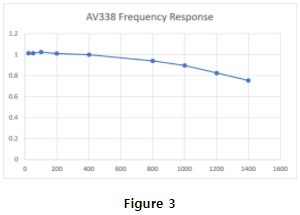

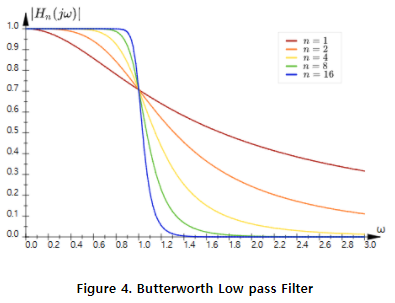

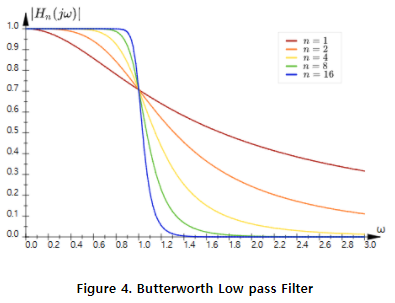

Table 1 is shown as the following figure.The detailed specifications of Digital Low-pass Filter used in MEMS Sensor are not mentioned in the data, but when comparing Figure 3 and Figure 4, it seems that the Butterworth 2nd order Low-pass Filter was applied.

Solution 2.

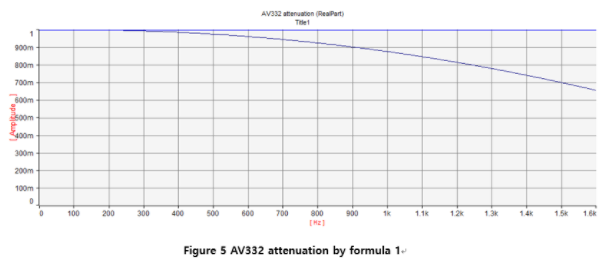

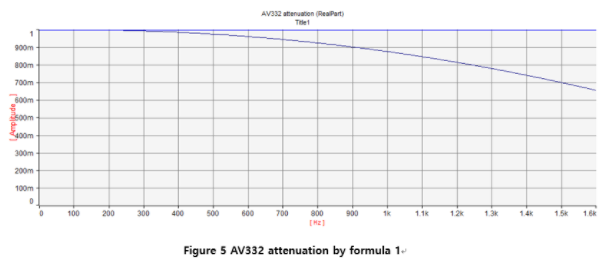

To prevent anti-aliasing, the use of a digital Low-pass filter is inevitable, and the portion attenuated by the Low-pass filter obtains the coefficient through the 2 order least square method.Compensation for the frequency response of AV338 is possible with the following formula.

attenuation= -1.54233801359415E-07*(freq)^2+0.0000335266124529598*(freq)+0.994254471503467 -formular 1

For example, since the attenuation at 1300 Hz is 0.777183943 when substituted into Equation 1, we can divide the attenuation value by 0.777183943 in the frequency analysis result.

In AV332, compensation for attenuation after 400 Hz can have excellent frequency characteristics with an error of less than ±1% up to the maximum frequency of AV332.

Issue 3. Frequency error occurs more than 1%.

It is judged that the frequency error generated by the MEMS sensor is generated by ADC sampling timing. The maximum sampling rate of the AV338 sensor is 6400 Hz. In order to generate exactly 6400 sampled data per second, the ADC requires a fairly accurate crystal. The cost pressure is quite high to use expensive crystals for MEMS sensors. The MEMS sensor used in AV338 is thought to have a sampling rate error of up to 1.5%, so let's think about how to solve this problem.

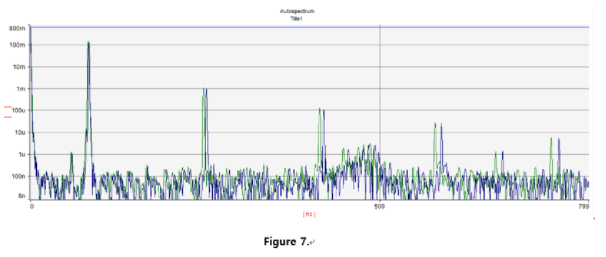

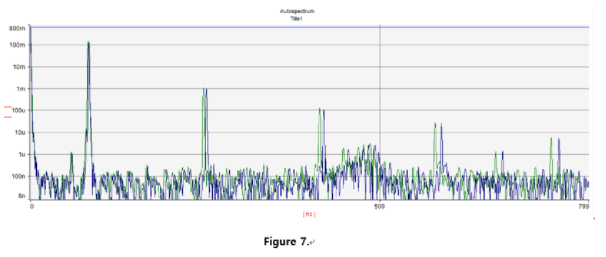

Green line: After compensate frequency

The creative items, AV332 Series by AVIIS include features and can be applicable to the following :

Features

- 3Axis Accelerometer

- 0~3200Hz Frequency range

- 2/4/6/8/16g Full scale range

- 12-bit data output

- 20*21*10mm small size

- USB Micro-B type connector

- External Battery

- Select Wi-Fi , USB, RS485 for data transfer

Application

- General vibration measurement

- Machine condition Monitoring

- Fence Intrusion Detection